"Clarion: Your Trusted Partner in Sealing Solutions."

Our Products

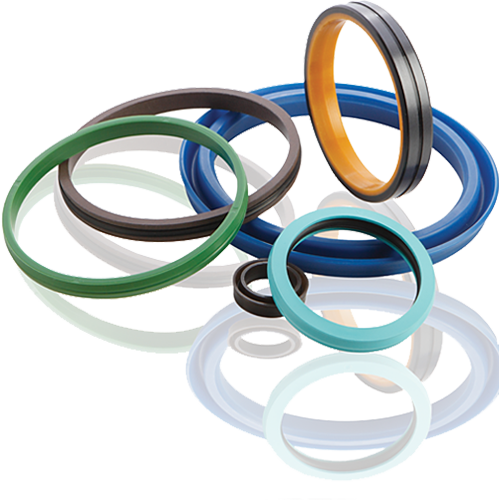

Gaskets

- Ring Gaskets

- Sprial Woud Gaskets

- IX Gaskets

- Bonnet Gasket

- Other Gasket

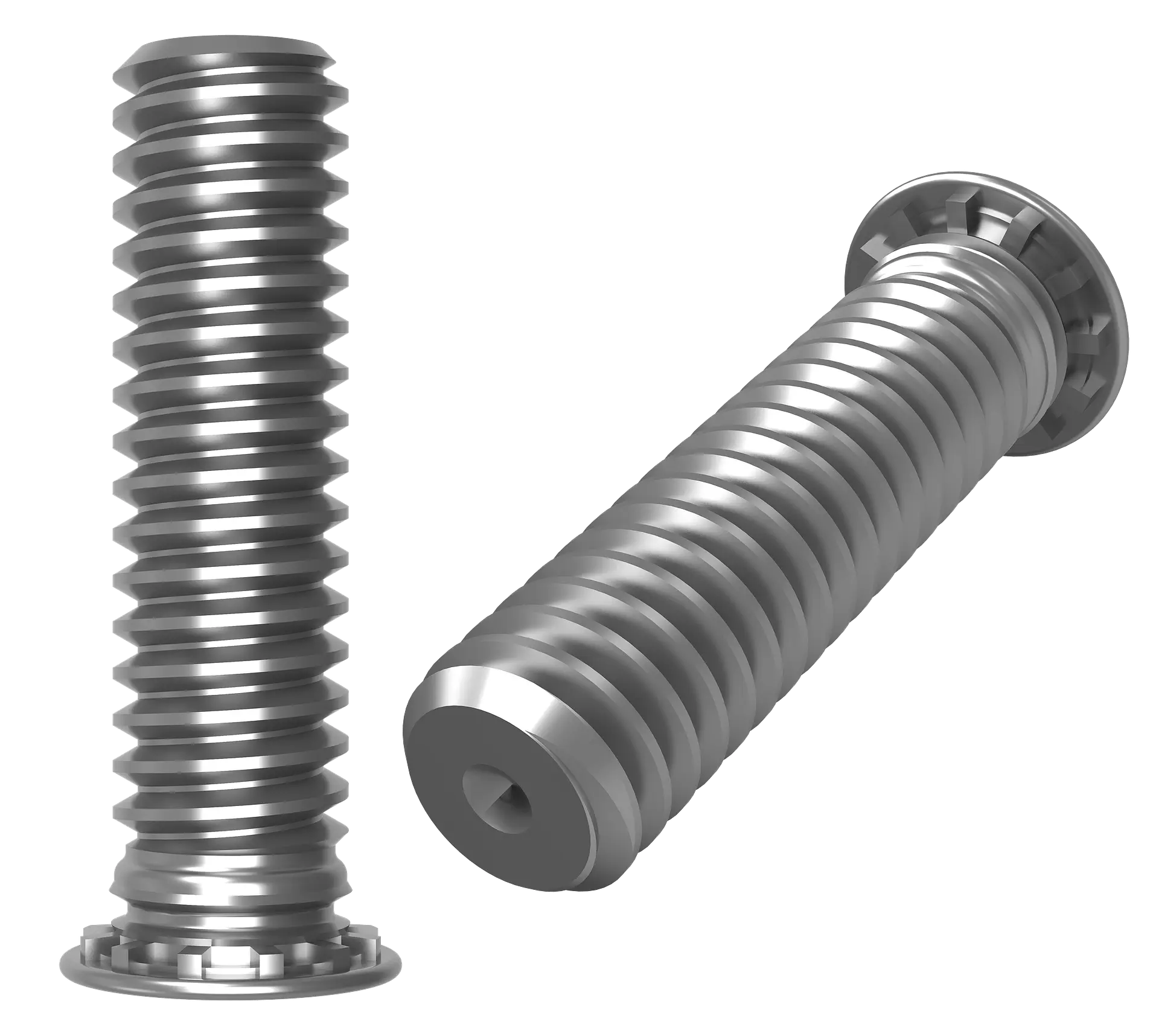

Studs

- B7 Stud set

- L7 Stud set

- 2H Nuts

Other Products

- Slip Dies

- Hammer Unions

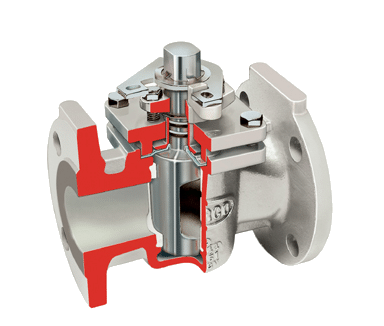

- Valve Seats

- Valve Componets

- Needle Valves

- Fittings

Industries We Serve

Oil and Gas

Mining

Valve Industry

Thermal Boilers

Pump Industry

Process Industry

Contact us

contact@clarionofp.com

713-922-8441

Houston, Texas

R (Oval) Ring Gasket

R (Octogonal) Ring Gasket

R (Octogonal) Ring Gaskets are R-Type, Ocogonal-shaped ring-joint gaskets suitable Primarily for various applications found in the Oil and gas Industry. They are manufactured in accordance with API 6A and ASME B16.20. standards, and are designed for high-pressure applications with a 23° angled sealing face Available in different sizes from numbers R11 to R105.

RX Ring Gasket

RX Ring Gaskets are designed for high-pressure sealing in demanding Oil & Gas, drilling, and petrochemical applications. Their unique design utilizes increasing internal pressure to enhance the seal. They are manufactured in accordance with API 6A and ASME B16.20. standards, and are designed for high-pressure applications with a 23° angled sealing face Available in different sizes from numbers RX20 to RX215.

BX Ring Gasket

BX-Type ring gaskets, compliant with API 6A abd ASME 16.20, are designed for API 6BX flanges and high-pressure environments (up to 20,000 psi). Every BX gasket features a pressure balance hole designed to equalize any pressure that might build up within the grooves. Available in different sizes from numbers BX150 to RX303.

IX Gasket

Bonnet Gasket

Clarion’s bonnet gaskets deliver reliable, leak-free sealing for critical industrial applications. Our gaskets withstand extreme pressures and temperatures. Available in various types and sizes, meeting API standards. Trust Clarion for precision-engineered gaskets ensuring safety and efficiency in oil & gas, petrochemical, and power generation.

Other Gasket

- Blind RTJ

- VX and AX Gasket

- Lens Gasket

- Combination Ring Gaskets

- Kammprofile Gaskets

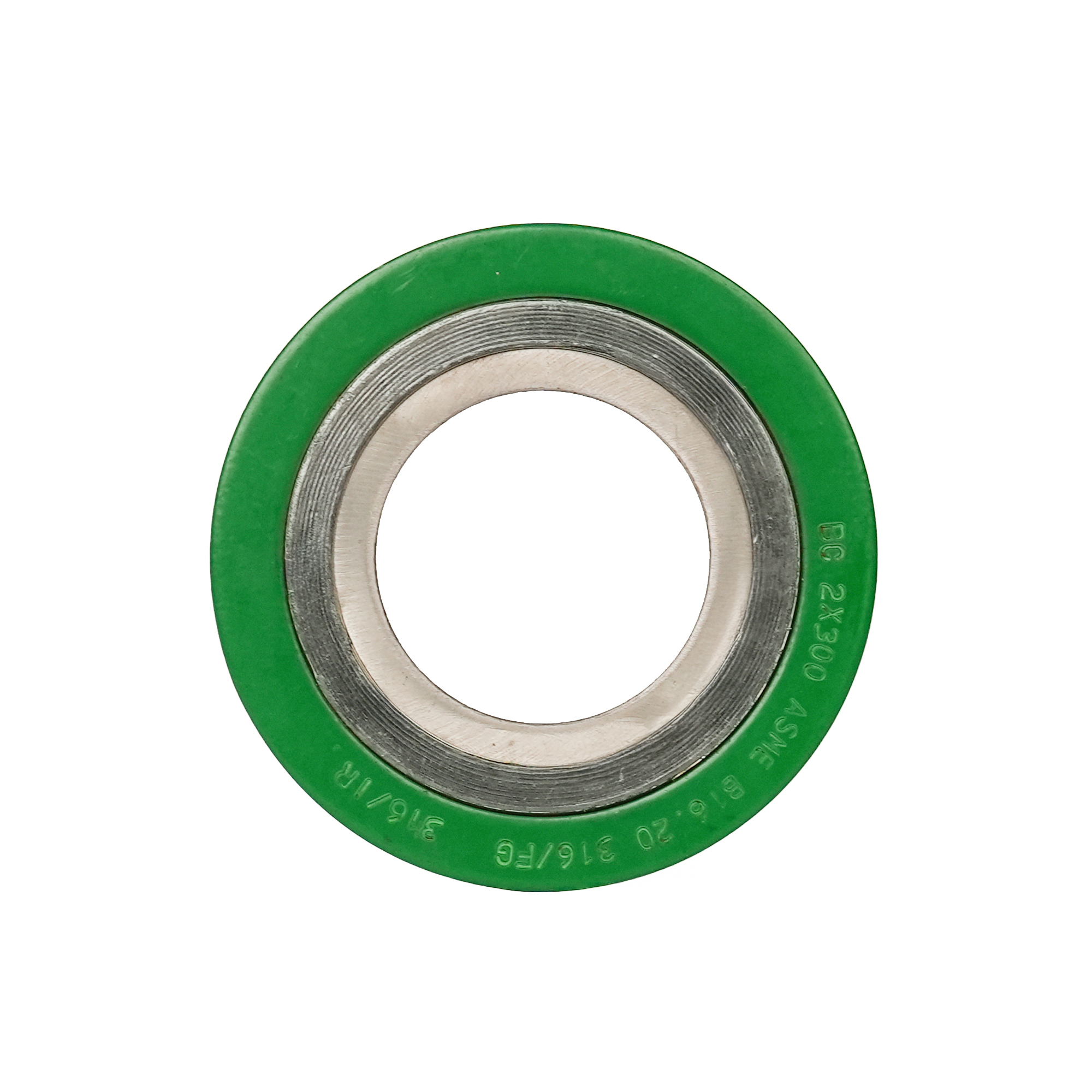

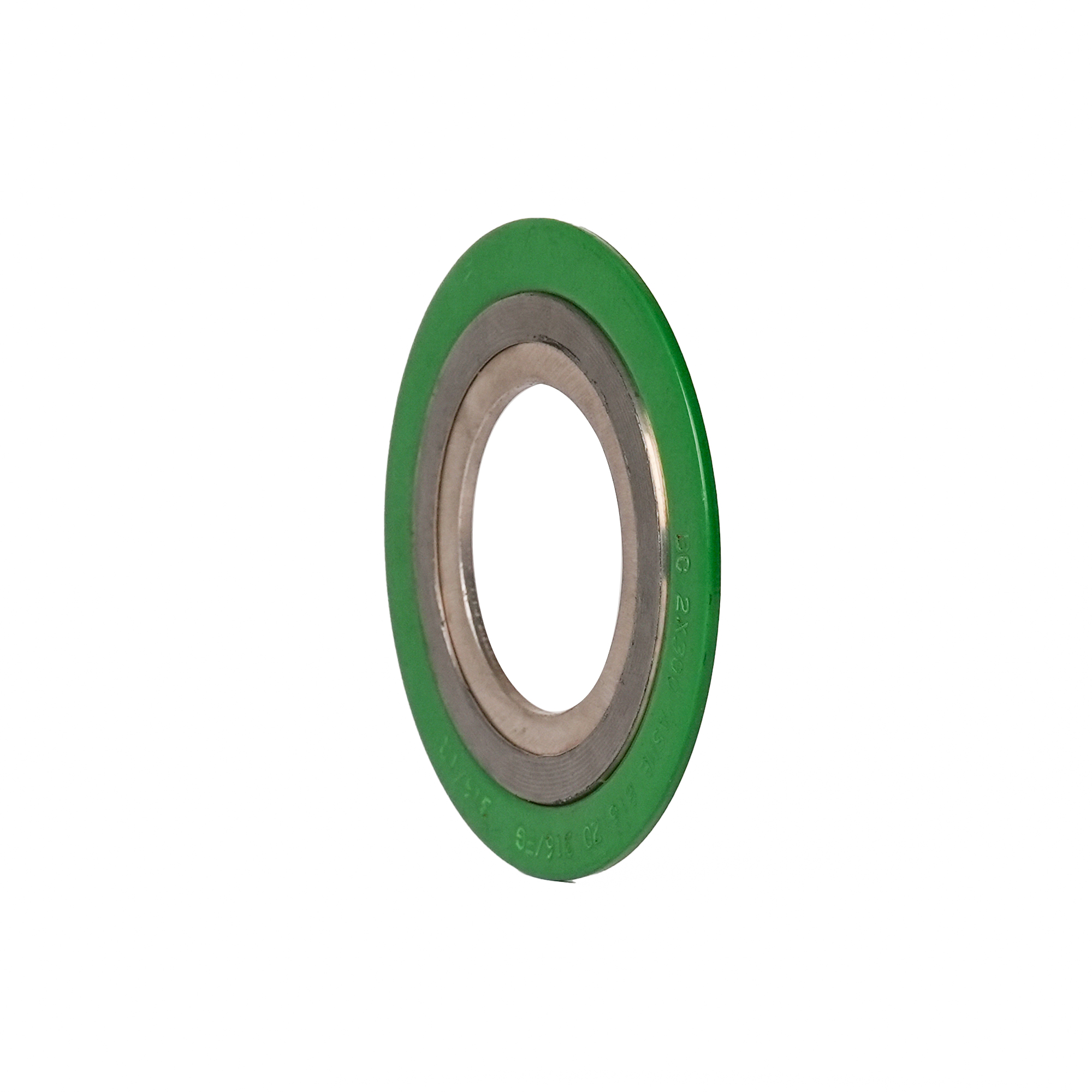

Sprial Woud Gaskets

R (Gasket only)

CG (Gasket with Outer Ring Only)

Clarion’s CG Spiral Wound Gaskets feature an outer centering ring, providing precise alignment within flange bolts. Ideal for high-pressure, high-temperature applications, these gaskets ensure a robust seal. Constructed with alternating layers of metal and filler material, they offer exceptional resilience and adaptability to varying operating conditions. The outer ring simplifies installation, prevents blowout, and enhances gasket stability. Available in diverse materials and sizes, Clarion’s CG gaskets deliver reliable, long-lasting performance for critical industrial sealing needs.

GI (Gasket With Inner Ring Only)

CGI (Gasket with Inner and Outer Ring)

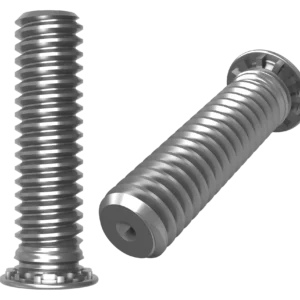

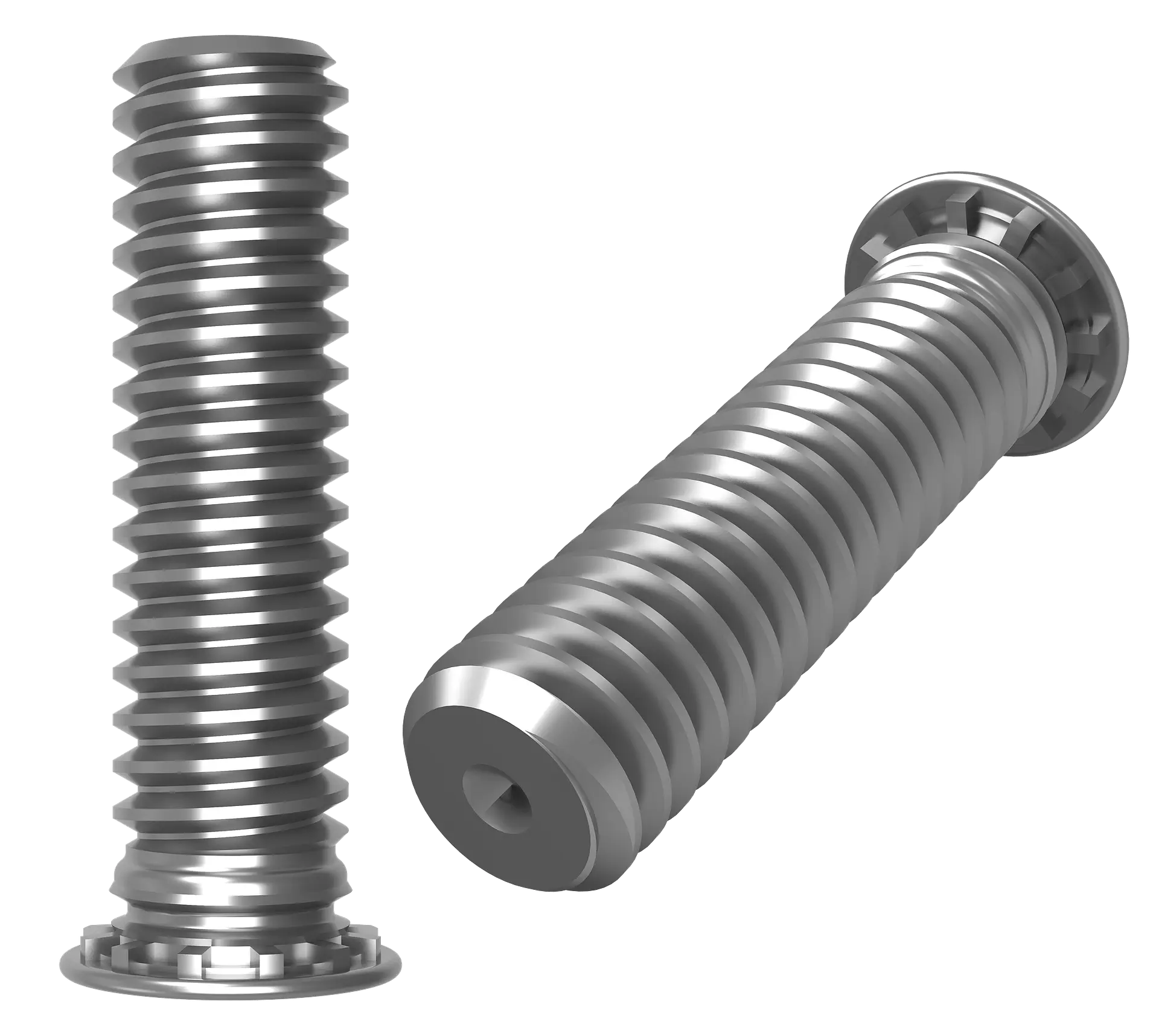

B7 Studs

Coating Options

- Black Oxide

- Black Phosphate

- Xylan Coating

- Zinc Plating

- Cadmium Plating

All Thread Studs

Tap End Studs

Combo Studs

L7 Studs

Coating Options

- Black Oxide

- Black Phosphate

- Xylan Coating

- Zinc Plating

- Cadmium Plating

All Thread Studs

Tap End Studs

Combo Studs

Other Products

Slip Dies

Hammer Unions

Valve Seats

Valve Componets

Needle Valves

Fittings

Online Store

-

Quick View

Select options This product has multiple variants. The options may be chosen on the product page Add To Cart View cartAdd To Wishlist

Select options This product has multiple variants. The options may be chosen on the product page Add To Cart View cartAdd To Wishlist$2,500.00Original price was: $2,500.00.$2,200.00Current price is: $2,200.00. -

Quick View

Select options This product has multiple variants. The options may be chosen on the product page Add To Cart View cartAdd To Wishlist

Select options This product has multiple variants. The options may be chosen on the product page Add To Cart View cartAdd To Wishlist

Capabilities

Casting

Forging

CNC

Coatings

Electroplating: White ZInc plating, Yellow Zinc plating

Quality Control

WAS 21 channel CCDspectrometer

Hitachi Foundry ProSpectrometer

Baird DV-6 1000mm41channel 6 basespectrometer

NITON PMIAnalyser

20MT UTM

Hitachi Foundry ProSpectrometer

Impact Testing M/c Portable

Hardness Tester Metallurgical

Microscope Radiation

Monitoring meter

Surface roughness measuring meter

Ultrasonic TestingM/c

Coating thickness measuring meter Height

Gauge, Digital Vernier, Pyrometers

Certificates

Machined Forged Products

Custom Manufacturing

Our state-of-the-art forging facilities are equipped to handle products up to a diameter of 1500 mm with a maximum weight of 100 kg. This allows us to cater to a wide range of specifications, ensuring every product meets the highest standards.

Complete Finishing Solutions

Our fully equipped machine shop boasts 24 advanced CNC machines, enabling us to provide comprehensive finishing services. From machining to fine-tuning, we ensure each product is delivered fully finished and ready for use.

Machined Casting Products

At Clarion, we specialize in delivering top-tier foundry services designed to meet your diverse casting and finishing needs. With advanced technology and unwavering dedication, we ensure precision and reliability in every project.

Melting Excellence

Our foundry is equipped with 350 KW and 125 KW power panels, boasting a rated output of 650 Kg/Hr and a monthly capacity of 300 MT. This enables efficient and consistent melting processes.

Casting Precision

Utilizing horizontal and vertical centrifugal casting machines, we cater to a wide range of specifications. Our machines support castings with a maximum outer diameter (OD) of 1100 mm and a minimum inner diameter (ID) of 25 mm. With a maximum pouring weight of 750 Kg (1250 Kg in select cases), we offer flexibility for diverse applications.

Finishing Services

Complementing our foundry capabilities, our fully equipped machine shop with 24 advanced CNC machines ensures seamless finishing to your cast products. From machining to polishing, every detail is handled with care and precision.

Technical Resources

Studs - Product Overview

Technical Specifications

Material Options

Carbon Steel

Alloy Steel

Stainless Steel

Heat-Resistant Alloys

Sizes

Diameter: 1/4" to 4"

Length: Up to 12'

Standards

ASTM

ASME

DIN

Coatings

Zinc Plating

Hot-Dip Galvanizing

Black Oxide

Custom Coatings Available

Mechanical Properties

Tensile Strength: Up to 150,000 psi

Yield Strength: Up to 130,000 psi

Hardness: Varies by material

Applications

Construction

Automotive

Oil and Gas

Marine

Gaskets - Product Overview

Technical Specifications

Material Options

Non-Asbestos

PTFE

Graphite

Metal-Reinforced

Rubber

Types

Sheet Gaskets

Ring Gaskets

Spiral Wound Gaskets

Custom Shapes and Sizes

Temperature Range

From -200°C to +700°C

Pressure Rating

Up to 1500 psi

Standards

ASME

API

DIN

BS

Chemical Compatibility

Resistant to Acids, Alkalis, and Solvents

Suitable for Hydrocarbon Processing

Applications

Chemical Processing

Power Generation

Petrochemical Food and Beverage

Quality Assurance

Our Commitment to Quality

Stringent Quality Control

We implement rigorous quality control measures at every stage of production. Our QA team conducts comprehensive inspections and testing to verify that all products adhere to strict specifications and tolerances.

Industry Standards Compliance

Clarion Industrial complies with leading industry standards to guarantee the quality and safety of our products. Our studs and gaskets meet or exceed standards set by organizations such as:

- API (American Petroleum institute)

- ASTM (American Society for Testing and Materials)

- ASME (American Society of Mechanical Engineers)

- ISO (International Organization for Standardization)

Advanced Testing Facilities

Our state-of-the-art testing facilities are equipped with the latest technology to perform a wide range of tests, including:

- Tensile Testing

- Hardness Testing

- Dimensional Inspection

- Chemical Analysis

- Pressure Testing

Continuous Improvement

Certifications

Clarion Industrial holds several quality certifications, demonstrating our commitment to maintaining the highest standards in our industry. Our certifications include:

- ISO 9001:2015

- API Q1 (for the oil and gas industry)

Customer Satisfaction

Quality Assurance Process

Material Sourcing

Manufacturing Excellence

Final Inspection

Documentation and Traceability

Api Flange Slide Rule

We have many satisfied clients

Adam Chuhan

Romanda Rio

Ronald Beko

Roman Kui